Concrete: The Durable Choice for Strong Planters

In public landscapes of various cities, large concrete planters brim with flowers and lush plants, enhancing aesthetics and supporting growth. Private gardens also favor them for unique designs. This article covers four key aspects: materials, plant adaptability, manufacturing, and reliable suppliers.

Explore the differences between cement and concrete, the suitability of concrete planters for plants, methods to make them lightweight and durable, manufacturing processes, and traits of a reliable supplier like Ronglin.

1. Cement vs. Concrete: What’s the Difference?

Cement, a fine powder made from limestone and clay, acts as a binder when mixed with water, sand, and gravel to form concrete—a versatile composite of cement, aggregates, water, and additives. Learn more at Ronglin Tech.

Cement undergoes high-temperature calcination and grinding to become hydraulic cement, hardening through hydration. Concrete, combining cement with aggregates, cures into a strong artificial stone for buildings, roads, and bridges.

Cement is vital for concrete, mortar, bricks, and tiles, supporting civil engineering and more. Concrete’s strength, insulation, and soundproofing make it ideal for skyscrapers, highways, and planters. While cement loses strength over time post-hydration, concrete’s cost-effective, durable nature shines. See our GRC solutions.

2. Are Concrete Planters Good for Plants?

Concrete planters benefit plants in certain conditions but come with challenges. They withstand outdoor elements, resist tipping in wind, and retain heat—ideal for plants thriving in warm roots, especially in cooler climates.

However, their porosity leads to faster moisture loss, requiring frequent watering. Untreated concrete may leach substances affecting plant health. They suit various plants if specific needs are met and issues managed. Check our planter care guide.

Ronglin, a leader in concrete and GRC, offers durable planters used for over a decade. Interested in bulk orders? Contact us for wholesale pricing.

3. Making Concrete Planters Lightweight and Durable

To craft lightweight, durable concrete planters:

1. Use lightweight aggregates (expanded clay, perlite, vermiculite) to cut weight.

2. Add fibers (fiberglass, polypropylene) for strength in thinner designs.

3. Optimize cement, sand, and water ratios for quality.

4. Design hollow sections to reduce material.

5. Apply sealers for longevity.

Key Considerations

- Aggregates: Lightweight materials need precise formulation to avoid mix issues.

- Fibers: Ronglin sprays GRC with glass fiber layers for strength. See our GRC process.

- Mix Ratios: Ronglin lab-tests ratios for optimal results.

- Coatings: We use natural minerals, avoiding harmful chemicals.

Balancing lightweight and durability requires experimentation. With 20 years of expertise, Ronglin offers proven solutions. Need bulk lightweight planters? Explore our catalog.

4. How Manufacturers Craft Lightweight Concrete Planters

Manufacturers like Ronglin produce lightweight concrete planters through a precise process:

1. Mix Preparation: Blend cement, lightweight aggregates (e.g., perlite), and fibers with water in tested ratios.

2. Molding: Pour into custom molds, often with hollow cores, to shape planters.

3. Spraying (GRC): For GRC planters, spray concrete-fiber layers onto molds for strength.

4. Curing: Cure in controlled conditions to ensure hardness without cracks.

5. Finishing: Polish and seal with natural coatings for durability.

Ronglin’s 20-year expertise ensures efficient production. Our GRC process minimizes weight while maximizing lifespan, perfect for wholesale needs.

5. Traits of a Reliable Concrete Planter Manufacturer

Fast Delivery

Long production cycles raise costs in developed markets. Ronglin’s multi-city bases cut delivery times, balancing employment and eco-friendliness. Learn more on our About Us page.

Customizable, Competitive Products

Ronglin’s designers offer full customization—materials, molds, processes, packaging—creating standout planters. Our best-sellers thrive on e-commerce, driving innovation. See options in our buying guide. Need wholesale quantities? Request a bulk quote.

In Conclusion

Concrete planters offer durability and heat retention for gardening, though their porosity demands extra watering. Lightweight, durable designs use aggregates, fibers, optimized mixes, hollow structures, and sealers. Ronglin, with fast delivery and custom options, leads the industry. Cement and concrete differ in use, yet planters excel with proper care. Read more on our blog. For distributors, contact us for wholesale deals.

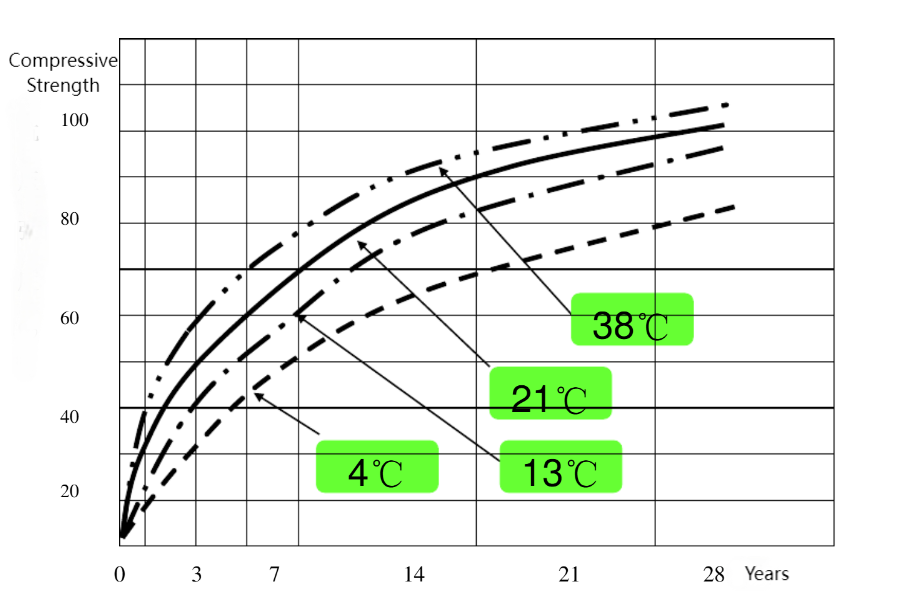

Concrete strength over time at different temperatures.

Portland cement, a concrete essential.

A thriving Ronglin GRC planter.

Crafting lightweight GRC planters.

Polishing for durability.

A step in planter production.

Ensuring planter quality.

Why choose GRC planters?